Fuji Electric, Differential pressure measurement

Differential pressure flow measurement is one of the most widely used measurement principles in the industry. The main field of application is the measurement of water in heating and cooling circuits and the measurement of steam and condensates at very high temperatures in secondary circuits.

Advantages:

- Suitable for liquids, gas et steam measurement

- Robust : only mechanical without moving parts

- Economical

- Easy maintenance : Associated electronics are out of the installation. No need to stop flow for equipment maintenance.

- Devices complying with International Standards

- Suitable for continuous flow monitoring

- Suitable for flow regulation

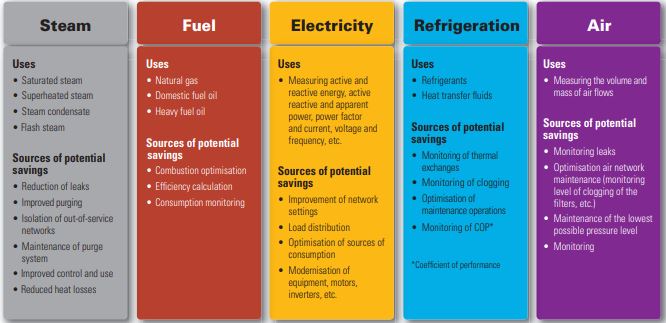

Energy optimisation of industrial processes.

Our solutions:

- Measurement

- Display

- Monitoring/optimisation of consumption.

Setting objectives:

- Global vision of the Company’s energy situation

- Identification of main areas for potential savings

Actions & results of energy audit:

- Reduction of production costs

- Increased productivity

- Improvement of quality

- Reduction of pollutants

- Implementation of energy efficiency management system

- Promotion of image as a socially responsible company

Solutions & actions:

- Corrective actions agreed upon by all parties involved

- Evaluation of investment costs/desired return on investment

Detailed analyses:

- Areas for potential savings

- Mapping out of energy needs

- Quantitative/qualitative image of production and evolution cycle over time via measurement campaigns

- Definition of progress and work axes.

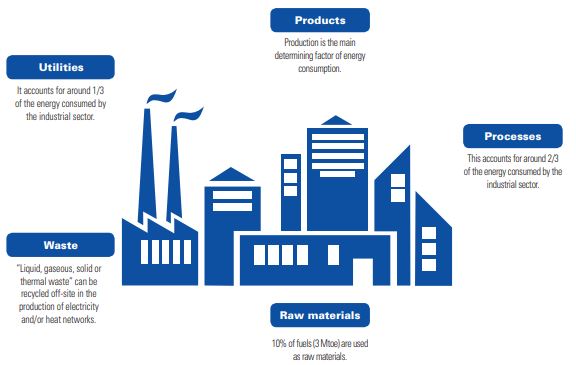

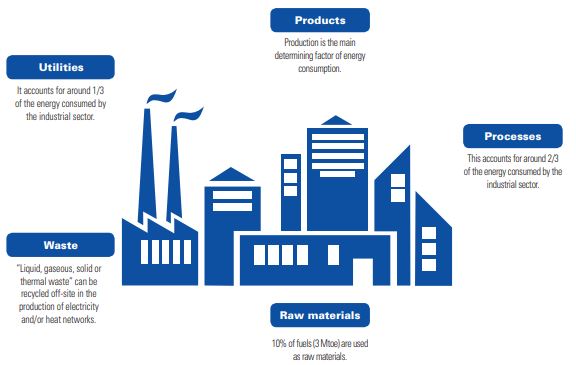

Today, all national and European regulations have the same aims: to reduce greenhouse gas emissions (GGE), increase renewable energy sources, and, above all, significantly boost energy efficiency. All industrial sectors are affected. The methods being used in each country and industry are different, calling for a flexible approach that has been designed for your specific requirements.

Measurement plan.

The measurement plan is drawn up in line with your industrial activity, ensuring that measurements are conducted in accordance with the extent of your consumption. Designed using information collected during the energy audit, this plan facilitates a level of development specifically adapted to your priorities. As such, energy losses are identified and good practice in terms of energy use is implemented in line with your budget.

Suitable measurements, a relevant acquisition system, management of your energy costs.

Fuji Electric engineers and technicians assist you in drawing up and implementing your measurement plan. Fuji Electric technologies are designed to measure and optimise energy consumption, allowing you to accurately measure your consumption and emissions, to calculate the efficiency of your installations, to establish energy performance indicators, to optimise your equipment, to improve the regulation of your processes, and to anticipate your needs.

Committing to an energy optimisation plan means :

- Freeing up financial resources and allocating them to the development of your core business

- Boosting performance levels

- Obtaining complete management of your utilities

- Continuously improving the performance of your production processes.

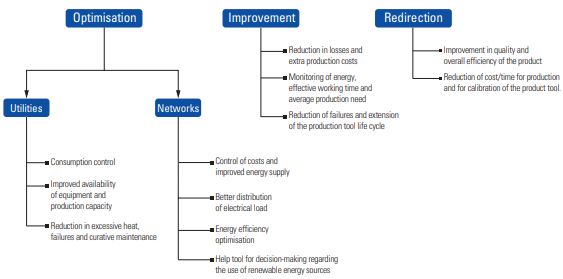

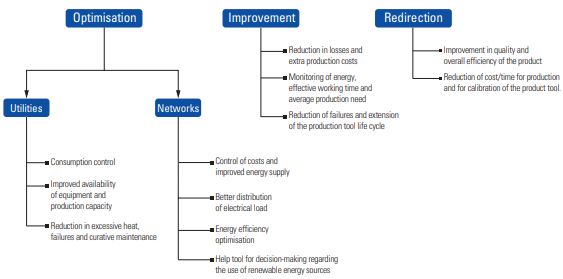

Fuji Electric expertise to optimise results:

- Optimisation of energy use

- Upgrading of production installations

- Redirection of resources to product manufacturing

- Optimisation of energy supply networks

Advantages:

- Suitable for liquids, gas et steam measurement

- Robust : only mechanical without moving parts

- Economical

- Easy maintenance : Associated electronics are out of the installation. No need to stop flow for equipment maintenance.

- Devices complying with International Standards

- Suitable for continuous flow monitoring

- Suitable for flow regulation

Fuji Electric industrial energy performance facilitates.

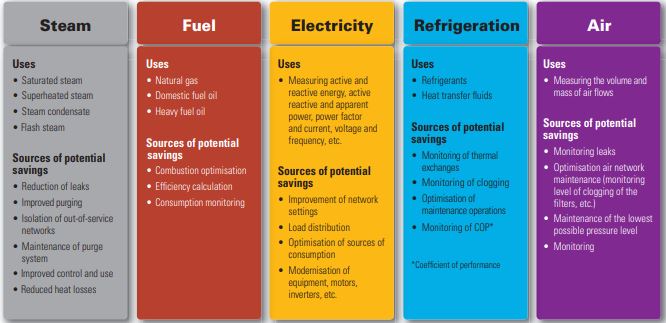

Energy optimisation of industrial processes.

Our solutions:

- Measurement

- Display

- Monitoring/optimisation of consumption.

Fuji Electric energy AUDIT, a real benchmark for your optimisation strategy.

Our energy audit is based on a methodical and rational approach that allows you to obtain a detail map of the energy you consume by your production tool. The different audit phases must be implemented in conjunction with the relevant technical managers, project managers, etc.Setting objectives:

- Global vision of the Company’s energy situation

- Identification of main areas for potential savings

Actions & results of energy audit:

- Reduction of production costs

- Increased productivity

- Improvement of quality

- Reduction of pollutants

- Implementation of energy efficiency management system

- Promotion of image as a socially responsible company

Solutions & actions:

- Corrective actions agreed upon by all parties involved

- Evaluation of investment costs/desired return on investment

Detailed analyses:

- Areas for potential savings

- Mapping out of energy needs

- Quantitative/qualitative image of production and evolution cycle over time via measurement campaigns

- Definition of progress and work axes.

Today, all national and European regulations have the same aims: to reduce greenhouse gas emissions (GGE), increase renewable energy sources, and, above all, significantly boost energy efficiency. All industrial sectors are affected. The methods being used in each country and industry are different, calling for a flexible approach that has been designed for your specific requirements.

Measurement plan.

The measurement plan is drawn up in line with your industrial activity, ensuring that measurements are conducted in accordance with the extent of your consumption. Designed using information collected during the energy audit, this plan facilitates a level of development specifically adapted to your priorities. As such, energy losses are identified and good practice in terms of energy use is implemented in line with your budget.

Suitable measurements, a relevant acquisition system, management of your energy costs.

Fuji Electric engineers and technicians assist you in drawing up and implementing your measurement plan. Fuji Electric technologies are designed to measure and optimise energy consumption, allowing you to accurately measure your consumption and emissions, to calculate the efficiency of your installations, to establish energy performance indicators, to optimise your equipment, to improve the regulation of your processes, and to anticipate your needs.

Fuji Electric monitoring and data analysis.

Fuji Electric’s Energy Managment System (FEMS) software uses proven technologies that take into account the consumption characteristics, and the energy storage and production of each specific industrial site. By combining and analysing the collected data (via an information processing procedure using large databases), we are able to optimise energy performance.Fuji Electric optimisation of energy efficiency.

Energy performance indicators are drawn up using your data. Providing an accurate gauge of the working condition of your equipment, energy performance indicators allow you to accurately and continuously monitor your consumption, to detect any possible deviations or malfunctions, to anticipate failures, and to optimise maintenance operations, etc.Committing to an energy optimisation plan means :

- Freeing up financial resources and allocating them to the development of your core business

- Boosting performance levels

- Obtaining complete management of your utilities

- Continuously improving the performance of your production processes.

Fuji Electric expertise to optimise results:

- Optimisation of energy use

- Upgrading of production installations

- Redirection of resources to product manufacturing

- Optimisation of energy supply networks

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_series.png)

_soft_starters.png)

.png)